5- Closed surge tank. The choice of Hydraulic Pump will depend on various factors including pressure flow.

Hydraulic Reservoir Design Considerations

A hydraulic systems functional and operational requirements.

. More retention time is likely needed for systems with grinder pumps or with large amounts of fat oils and grease. There are several key considerations in the hydraulic design of water storage. Company standard which has been around for years states that oil passage cutouts have an area at least 2-12 times the total pump inlet area No one can tell me where this requirement came from.

Cooling considerations The reservoir often just called the tank also provides significant surface area for cooling of the hydraulic fluid. The paper presents the development of industrial 400 litre hydraulic tank. When designing a hydraulic system clear operational specifications must be identified for the user such as.

Tank sizing should also account for the. More retention time is likely needed for systems with grinder pumps or with large amounts of fat oils and grease. Numerous decisions must be made in designing a storage tank including size location type and expected operation.

Different sizes and designs are available for the HIT. Another important design consideration is tank port placement and size. 3- 2013 - 148 -.

An important aspect of pump hydraulic system design is the suction or inlet conditions. In addition some systems that have proportional or servo valves may also be highly sensitive especially to fluid contaminants. Disregard for proper allowances can result in vortices cavitation and loss of prime.

Surge Tank Design Considerations for Controlling Water. Hydraulic tank design is often neglected part of the development. October 20 2014 By Josh Cosford.

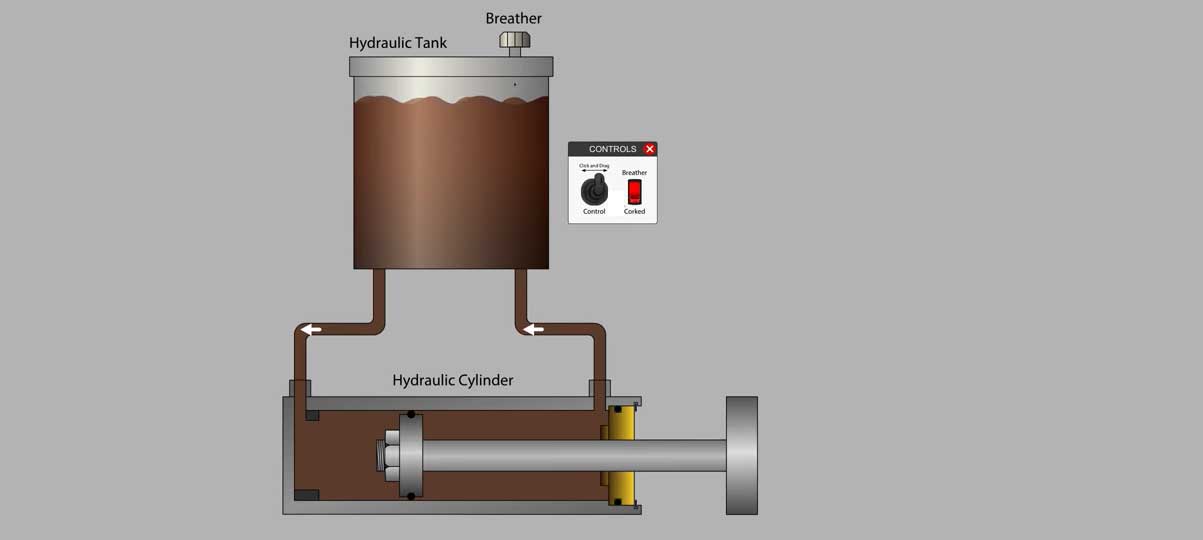

Overfilling should avoid during the servicing of the hydraulic tank. Hydraulic tank design is often neglected part of the development. In this chapter the word tanks will be used to describe treated water-storage facilities although the term reservoirs is.

Standpipes and elevated storage tanks should be located at least three feet above the 100-year flood. This article has been written to fuel the imagination of design engineers working on Hydraulic Tanks. When designing the optimum hydraulic reservoir most of the considerations are in keeping the oil clean and cool.

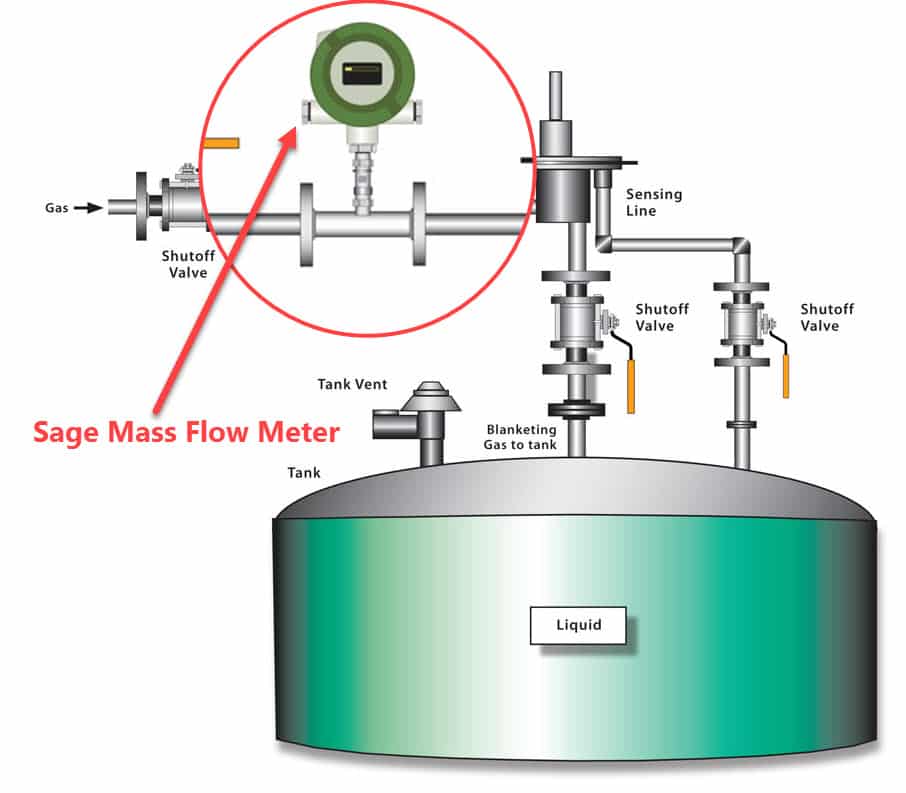

Except for all these factors mentioned above a style capacity shape material porting placement and venting are essential elements that you need to consider while selecting a hydraulic reservoir. Types of allowable fluids. In order to reduce oil swirling and improve stability of fluid flow CFD simulations of oil flow inside hydraulic tank were made.

Located at least 50 feet from any part of a subsurface sewage disposal system or sanitary sewer and. Ad Denison Hydraulic Pumps And Motors Available. According to this study the surge tank.

Dimensions could be estimated theoretically as follows. Septic tanks for commercial systems are recommended to have at least three days of design hydraulic retention time with four-plus days for challenging streams. This chapter focuses on the hydraulic aspects of design as opposed to structural corrosion safety contamination or instrumentation aspects.

Several variations of new hydraulic tank designs are compared. An orifice tank having a riser is called differential tank. Rotational Moulding - Hydraulic Tank Design.

There are several key considerations in the hydraulic design of water storage tanks. Surge Tank Design Considerations for Controlling Water. An increase in fluid volume and calculation of thermal expansion also need to consider.

Safety emergency and energy isolation. The pump inlet and return ports should be on opposite ends of the reservoir to allow the returning oil to lose heat before again being drawn into the system. In a one way surge tank the liquid flows from the tank into the pipeline only when the pressure in the pipeline drops below the liquid level in the surge tank.

Station Layout Considerations Provide sufficient work space between pumps Use largest pump and motor dimensions now or future Allow for expansion Think through process of installingremoving pumps and valves Size crane and openings for heaviest largest single item in the station Ensure crane can reach everything it needs to lift. Proper suction piping design and installation considerations consist of pipe and pipe fittings and their relationship quantity and relative location to the pump. 4- One- way surge tank.

It seems like there would be a better way of determining the amount of open area. Reservoirs in industrial applications are spoiled by the extra. 3- Differential surge tank.

Septic tanks for commercial systems are recommended to have at least three days of design hydraulic retention time with four-plus days for challenging streams. Numerous decisions must be made in the design of a storage tank including size location type and expected operation. Looking for rules of thumb on baffle design for hydraulic tanks.

2 Section 19-13-B102f5B of the RCSA requires in-ground finished water storage tanks to be. Performance and Function Considerations of Hydraulic Tanks. University Bulletin ISSUE No15 Vol.

Hydraulic system design considerations The most susceptible components in any hydraulic system are the pump motors and cylinders. Hydraulic oil spends most of its time in the reservoir and as such various tank design criteria provide benefits for the hydraulic system as a whole. Standpipes and elevated storage tanks should be located at least three feet above the 100-year flood.

Hydraulic Powerpack Design Considerations Primary Driver. If the top of the tank is closed and there is. The paper presents the development of industrial 400 litre hydraulic tank.

Surge tank cross-sectional area is about 400 500 m2 which is corresponding to a first upsurge of about 3 4 m respectively. One of my clients a Rotational Moulding manufacturer Amber Plastics has expertise and a great deal of experience in the field. The primary driver is the component that will drive the hydraulic pump and in turn develop a flow of.

Looking for rules of thumb on baffle design for hydraulic tanks.

Troubleshooting Hydraulic Reservoirs Breathers And Filters

Nitrogen Blanketing And Tank Blanketing Flow Meters

Some Vital Information About Spandrel Beams Civil Engineering Design Beams Structural Engineering

Hydraulic Elevators Basic Components Electrical Knowhow Hydraulic Systems Elevation Indoor Lighting Fixtures

Hydraulic Reservoir Design Considerations

Hydraulic Reservoir Design Considerations

Practice Good Hydraulic System Maintenance

Water Worker 62 Gal Pressurized Well Tank Ht62b Well Tank Pressure Tanks Rain Water Collection System

0 comments

Post a Comment